Primary Framing is the Skeleton Under Every Steel Building

John Lohan • January 12, 2026

Strength and stability – what primary framing hides from sight.

When work begins on a pre-engineered steel building job site, the first sign of what will come occurs when that steel skeleton appears; tall, vertical girders reaching into the sky. Of course, a considerable amount of work had gone into the building project long before any metal ends up on site. The arrival of steel I-beams forms the initial major stage of construction and it is one of the most important phases of building installation.

To learn about these early stages, we welcome you to

read about the site excavation, foundation and concrete work we do.

Primary framing (also known as structural framing) is to steel structures to what bones are to the human body. It's the skeleton providing strength, protection and support for all the other materials and systems. Steel framework’s importance to the resiliency and strong performance of buildings is so critical but does not usually get the attention it deserves. I-beams and girders are not the sexy part of the building, but the more glamourous and fashionable exterior finishing materials cannot exist without them.

Let’s take a closer look at various types of primary framing Double Black Construction

typically installs, how they impact the shape and design of the final building, and how different architectural features are only possible by using the high strength-to-weight ratio steel provides.

A Variety of Framing Systems to Use

Metal buildings, for the most part, use one of the three main categories of primary framing:

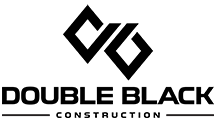

- Clear Span Framing: This system is most often used in buildings where unobstructed interior space is desired. Think of larger commercial or industrial structures that include common uses such as aircraft hangars, hockey and riding arenas, golf/tennis/soccer centers, warehouses and manufacturing facilities. Column-free interiors offer the wide-open space for a variety of activities and layouts that only steel framing can allow. Clear span framing can allow up to 300 feet A ridged steel-frame clear span system creates open space up to 300 feet (91.44 metres) wide with bay spans up to 60 feet (18.3 metres).

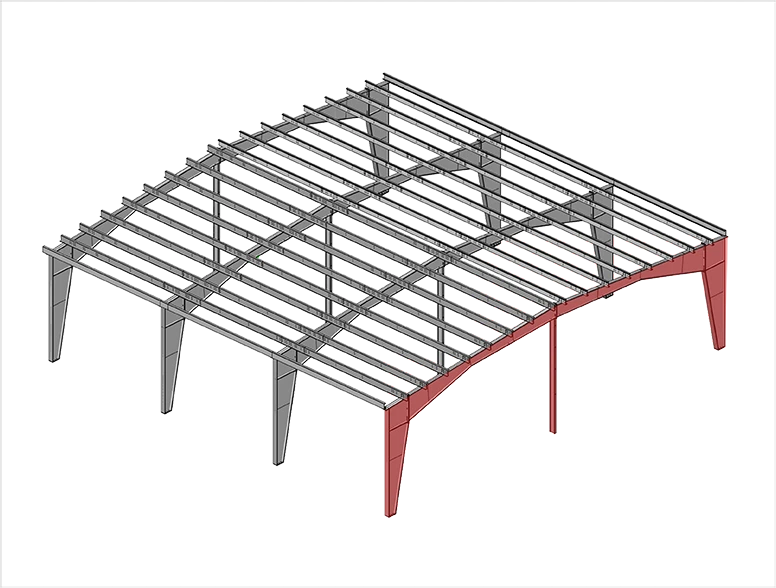

- Multi-Span Framing: Commonly used for building layouts that permit interior columns, multi-span systems offer more flexibility in building layout. The spacing between columns can vary to meet any requirement with open floor spacing being met with a minimum of pillars. Smaller commercial structures, including retail and office stores, tend to prefer this architectural design.

- Lean-To Framing: With an asymmetrical and interesting design appeal, this framing type is popular for economic expansions to existing buildings. A lean-to frame typically uses a single slope (without a ridge) and straight sidewall columns that must be supported with an attachment to another frame.

Images courtesy of Robertson Building Systems. We are one of their authorized installation partners. To learn more about our relationship, see “Get to Know Our Building Partner”.

The Structural Strength (and Design Possibilities) of Steel Framing

Steel has become the material of choice for commercial and industrial buildings due to its high strength-to-weight ratio, high tensile strength, and ability to support heavy loads. Steel framing provides the backbone that makes it ideal for large-scale projects that demand resilience and stability.

Modern pre-engineered metal building (PEMB) framing systems are the basis for robust structural strength that easily adapts to architectural intent. Long clear spans, modular framing, wide-open interiors and extensive customization options allow architects to sculpt space in ways that would be too costly – or even impossible – with conventional construction using wood timber or brick and mortar.

Creative architectural elements such as curtain walls, cantilevers, energy-efficient façades, glass features, multi-storey mezzanines and geometric rooflines all integrate seamlessly with engineered steel frameworks. This versatility gives building manufacturers, architects and their clients the freedom to experiment with form while maintaining engineering integrity.

Regardless of Business Use, Every Metal Building Starts with an Ideal Framing System

Building system manufacturers

and their clients expertly work to design a building that meets their operational needs and design wishes. Once the design is complete, engineers

get to work to incorporate the underlying steel framing system into the design and build the components that Double Black Construction

will install on their behalf. The shape and use of the building will help determine which primary framing structure to use.

The appropriate steel framing system is chosen to support unlimited opportunities for contemporary design and architectural features. Architects

and manufacturers

create the building and its components parts; Double Black Construction

turns those designs into reality at your job site, regardless of which framing is selected. We exclusively work with pre-engineered metal buildings systems – it’s the only thing we do.

For more information or to get started on your next project, contact John Lohan to get a free quote by contacting us today

or calling

(833) 322-2722

to speak directly with

our leadership team.

About the author:

John Lohan

has over 20 years of experience designing, engineering and installing over 500 metal buildings for architects and clients across North America and the globe. He’s managed all aspects of steel building construction, including material logistics and managing local and foreign construction teams. John also has special expertise in concrete foundation and excavation. He can be contacted at Double Black Construction at (833) 322-2722, by email at info@DoubleBlackConstruction.com

or on LinkedIn.