The Great Mix-Up: Concrete and Cement

John Lohan • November 21, 2023

If a solid concrete foundation is so vitally important for the strength of your building construction,

how come installers spend so little time discussing it with clients?

Let us explain what makes concrete so critical for your building’s durability.

Concrete is literally the foundation for most modern commercial and industrial construction projects. It is the most widely used building material in the world, used for roads, bridges and buildings and is behind only water as the planet's most-consumed resource. Architects and engineers couldn’t create large buildings and skyscrapers so strong and tall without it.

While most people rarely think about the hard substance under their feet, the construction team at Double Black Construction thinks about it all the time. Working with the material to create a proper building foundation is the first, and one of the most important, stages of industrial and commercial construction. Not all pre-engineered erecting teams also create the foundation. For something so important, it only makes sense to hire a single turnkey construction partner with expertise in all facets of construction; from laying the concrete foundation to doing the final interior finishing

A Secure Concrete Base Creates the Necessary Stability

Buildings Require to Stand the Tests of Time

Buildings Require to Stand the Tests of Time

A solid concrete foundation is a fundamental structural component for securing the columns and framework of pre-engineered steel buildings. It helps spread massive weight over a larger surface area and secure everything on top of it against vibration and shocks. Smaller buildings can start with a single concrete slab for support, while in soft soil and various other types of looser ground, metal or wood piles are driven through sand or snow down to the solid bedrock deep below.

After surveying and excavating the building area, poured concrete slabs (sometimes snaked with heated wires or water pipes to provide warmth and to prevent ice buildup in exterior uses) are the most ideal foundation for most building sizes. The concrete sits atop a base of gravel, fabric sheets (to prevent plants from drilling through) and wire mesh that prevents the large concrete surface area from cracking or buckling. In cases where the building lies in a winter climate, larger areas are cut into smaller sections so they can shift slightly (fractions of a centimetre) without splitting or breaking.

As the name suggests, a poured concrete slab is simply a thick, flat section of concrete (usually between six and eight inches thick) that is poured and shaped using wood or extruded polystyrene forms. The forms hold the wet concrete in place until it dries. With pre-engineered steel buildings, the supporting girders and frames for wall and roof systems (and possibly mezzanines or upper floors) are also reinforced with concrete footings. These thick sections of concrete are blocked up under load-bearing walls and physically set alongside the steel to create an immovable force. Larger slabs and foundations for multi-story buildings may also contain rebar (metal rods wired together to create strength).

The finished concrete floor is then treated with curing compounds, coated and sealed and then covered with whatever other materials clients want (such as bamboo, wood, stone or other) for both aesthetics, soundproofing, comfort and to provide additional resistance to damage. For industrial purposes, the treated concrete can be left as is. Either way, the building starts with a reliable and stable base that resists damage, is smooth and flat and looks great.

Don’t Call It Cement (and it’s definitely not brought in by a cement truck)

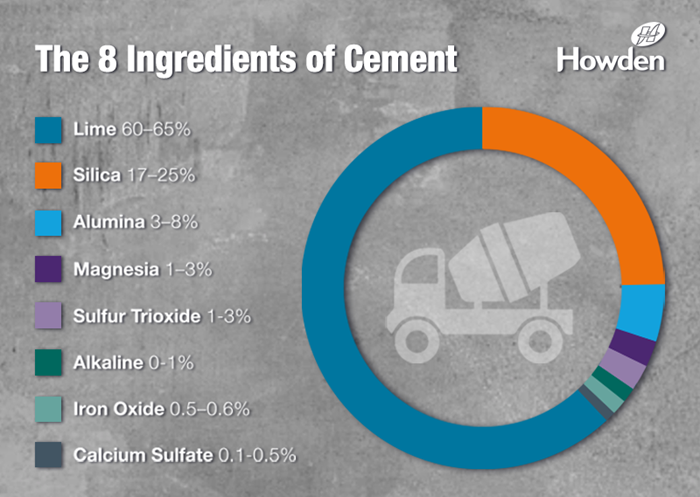

Cement and concrete are different. People often use the terms interchangeably, which is similar to amateur or home bakers using the words ‘flour’ and ‘cake’ interchangeably. The materials are not the same. Cement is an ingredient in making concrete, the fundamental building base for most buildings. Although concrete is instrumental to modern construction, it is not a recent innovation. The builders of the Roman Empire relied on the material for most of the infrastructure

(such as aqueducts) and buildings.

Cement is a binder, a chemical substance used for construction that sets, hardens and adheres to other materials to blend them together. Cement is seldom used on its own, but rather in combination with aggregates (a mix of sand, gravel or crushed stone) together.

According to the Cement Association of Canada, 15 cement plants across Canada “ship cement to more than 1,100 associated facilities. Collectively, the cement industry supports about 158 000 direct and indirect jobs across the country and contributes CA$76 billion in economic benefit to the Canadian economy.”

If you’re curious what can happen to the construction industry even when the cement industry temporarily shuts down, read about the significant impact a five-week cement strike in Vancouver had during May and June of 2022:

Cement + Aggregates + Water = Concrete

Many people might remember an episode of “M*A*S*H”

where they try to lay a concrete floor in the operating room and fail to get the ratio correct, resulting in a muddy soup instead of a solid base. To make concrete, you need to use a specific formula of cement, water and aggregates. The ratio can vary slightly but it starts with approximately 10 to 15% Portland cement (“Portland” is the generic term for the type of cement used in almost all concrete) and 15 to 20% water that is turned into a paste. It is then mixed with 65 to 75% aggregates. As the cement and water mix, they harden and bind the aggregates “into an impenetrable rock-like mass”.

It is concrete that we associate with the strong, durable, structural building material used widely in construction for bridges, buildings and sidewalks. And cement is the main binding ingredient within it.

Double Black Construction forms working relationships as strong and reliable as concrete

For the construction of pre-engineered steel buildings specifically, good-quality concrete bases are essential to create a durable and stable structure that will last for generations. When clients buy a metal building solution from their manufacturer, they often left on their own to find a building partner to build a foundation and install the structure. With Double Black Construction as your first choice and turnkey building partner, our experience in all stages of pre-engineered construction means you can leave the details to us.

Engineers, architects and building system manufacturers can rely on Double Black Constructions’ experienced team

to prepare all aspects of the building plan, to specification, and execute it on time and on budget. Concrete is not the only part of the job we do; however, our team delivers it to the same high standard as the rest of our construction and installation work. Why rely on multiple subcontractors when one turnkey partner will do everything you need?

Contact John Lohan and his team

at Double Black Construction online

or speak with us at (833) 322-2722

and we’ll provide you with a free consultation and quote.

About the author:

John Lohan has over 15 years of experience designing, engineering and installing over 500 metal buildings for architects and clients across North America and the globe. He’s managed all aspects of steel building construction, including material logistics and managing local and foreign construction teams. John also has special expertise in concrete foundation and excavation. He can be contacted at Double Black Construction at (833) 322-2722, by email at john@DoubleBlackConstruction.com

or on LinkedIn.